Utility Concrete Products Company Limited (UCPCL) is a concrete pre-cast manufacturing company that seeks to supply precast commodities to the Caribbean housing, infrastructure and utilities sectors. The Company was originally founded by Engineer Vincent Bowles and specialised in the production of ferro-cement (thin-walled concrete) septic tanks and sewage systems. The Company now seeks to specialise in the design and manufacture of pre-cast houses.

"Enimad minim veniam quis nostrud exercitation

llamco laboris. Lorem ipsum dolor sit amet"

In the construction industry, adhering to codes is fundamental for safety, efficiency, and compliance. At UCPCL, we prioritize the importance of following established building and engineering codes, ensuring that our designs and products not only meet but exceed industry standards. Our commitment to these codes is reflected in our meticulous design process, where each component is analyzed and tested to comply with local and international regulations. This adherence to codes is a testament to our dedication to quality, safety, and sustainability, providing our clients with peace of mind and structures that stand the test of time.

Services and Products – Design Flexibility

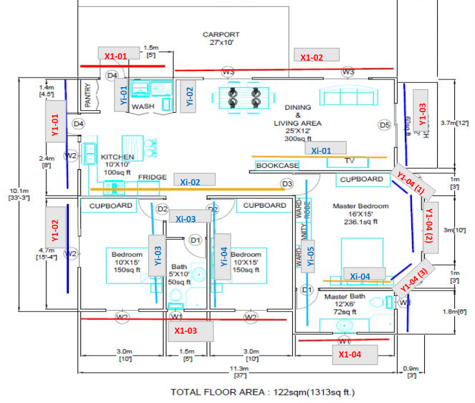

UCPCL provides design flexiblity to the Client, whether they be an individual home owner or larger property developer. Each client has the option to submit their own architectural drawing design conceptualization of the layout of their dream home. This gives the Client full control of a bespoke design from the ground up specific to their personal requirements.

Alternatively, for Clients who do not have completed architectural drawings, UCPCL can make the design phase easier by providing a consulting architect or a technician. For Clients who request to engage the services of our in-house architect or technician, this phase would require more time to complete the required drawings before moving to the next stage of measuring and quotation. When final design drawings are submitted, UCPCL will now progress to the next step.

Alternatively, UCPCL has a range of “off the shelf” designs, that can be modified to the Client’s preferences.

At UCPCL, our engineering design process and commitment to quality are at the core of everything we do. From the initial concept to the final product, our team of experienced engineers utilizes the latest technology and innovative practices to ensure each design is optimized for performance, durability, and aesthetics. Our rigorous quality control measures ensure that every product meets the highest standards of excellence, delivering reliability and satisfaction to our clients. With UCPCL, you can trust in our expertise to bring your vision to life with precision and integrity.

Once the Architectural floor plans and elevations are finalised, UCPCL’s Engineers model and analyse building structure in our structural design software ROBOT AutoDesk, to ensure resistance against the gravity, earthquake and wind loads.

Once the stresses experienced by the structure are determined and all elements, materials and connections are accurately specified, the model is transferred to our Building Information Management (BIM) software, REVIT AutoDesk for preparation of fabrication drawings. These are then used by the factory for manufacturing of the individual components.

to save your favourite homes and more

Log in with emailDon't have an account? Sign up

Enter your email address and we will send you a link to change your password.

to save your favourite homes and more

Sign up with emailAlready have an account? Log in